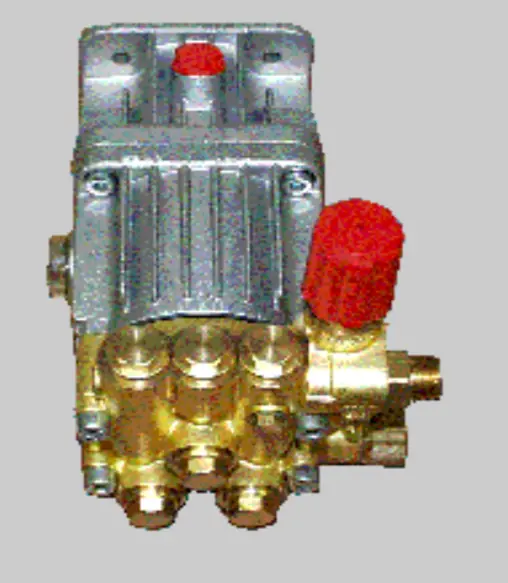

FEATURES:

- Regulating unloader valve

- Tamper resistant operator adjustable valve which allows limit setting on both maximum and minimum pressure

- Ideal for steam combination applications

- Straight flow-through design minimizes pressure loss through valve

- Working components constructed of high grade stainless steel, teflon, and Viton seals for maximum heat/chemical resistance

- Internal bypass valve can be easily accessed and repaired without removing unloader from unit

- True to Suttner design tradition, valve is cartridge type and installed in minutes

- Pressure adjustment knob can be removed if desired

SPECIFICATIONS:

- Downstream injection at 10:1 rate

- Low pressure limit setting eliminates need of additional metering devices

- A downstream chemical injector relies on pressure loss through a restrictive orifice, which is built in on the ST-261 restriction AFTER the orifice must be minimized in order for injection to occur. Therefore, this system must incorporate a large orifice spray nozzle which reduces such restriction. It is generally recommended the usage of a nozzle with a minimum orice size of 30.0. Samller nozzles may be used, but the added restriction may result in ineffective suction rates or no suction at all. In addition, remember that fittings and even hose add to the restriction within the system and may affect or eliminate the suction capabilities

- Pressure Rate: Up to 3650 PSI

- Flow Rate: 1.5 to 2.25 GPM

- Temperature: 176 F

- Inlet: 3/8″ FPT

- Outlet: 3/8″ FPT

- Bypass: 1/4″ FPT

- Gauge Port: 1/4″ FPT

- Weight: 22.5 oz