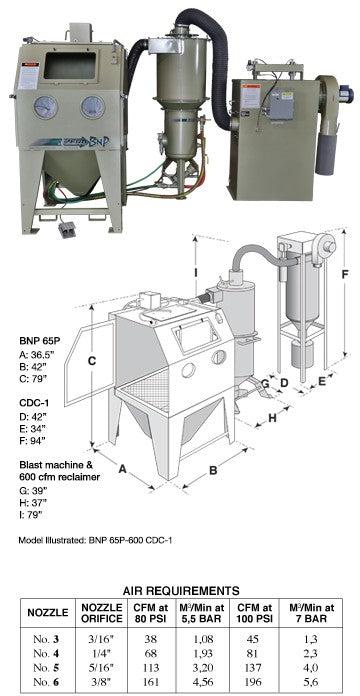

BNP blast cabinets deliver efficient, affordable media blasting to clean, peen, deburr, or finish parts. The BNP 65 (enclosure size: 36 by 36 by 38 inches) is available in suction and pressure blast models, and accepts popular options – turntables and tracks for heavy parts, vertical doors to speed loading, and other Options Plus modifications. Shown with 600 CFM reclaimer (rear mounted) and dry filter dust collector. Also available with optional reverse-pulse dust collector.

For tough cleaning jobs, pressure blasting delivers higher abrasive velocity for greater impact intensity, compared to suction blasting, and can increase your production rate by as much as 300 percent.

Safety

- Full-length, neoprene-on-fabric gloves resist wear and protect operator.

- Ceiling-mounted, two-tube fluorescent light fixture with abrasive resistant Lexan™ cover for extraordinary visibility.

- Safety interlocks interrupt blasting if either door isopened. (Conforms to US regulations.)

- Adjustable, heavy-duty chromed latches seal doors tight through years of service.

Productivity

- High efficiency, 2.0 cubic foot capacity, ASMEcoded pressure vessel, fitted with 1″ ID piping, industrial-quality blast hose and couplings and cabinet integrated controls.

- Unique Air Logic system (pilot actuated) to maximize air flow to the blast gun.

- Double-wall, sound-insulated doors, with industrial quality lift-off hinges.

- 14-gauge steel all-welded construction, with precisely formed bends, forms a rigid, long-lasting cabinet shell.

Convenience

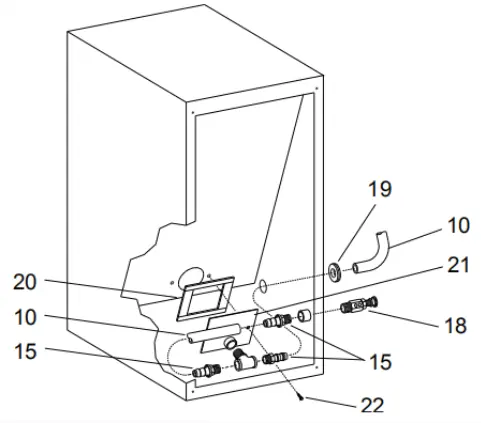

- Tilt-out window, for tool-free glass changes in minutes.

- Pressure regulator, gauge, and electric switch mounted within easy reach.

- Built-in blow-off gun helps keep dust inside the cabinet, not on your floor.

Common Applications

- Remove rust, mill scale, heat scale, and carbon buildup from metals

- Strip paint, powder coating, plating, and anodizing from parts for rework

- Eliminate burrs, parting lines, flashings, and other defects from castings and injection-molded parts

- Extract residual sand from castings

- Beautify steel, stainless steel, aluminum, brass and other metals with a uniform matte finish

- Etch artwork and lettering into glass, stone, plastics, metal and other materials

- Clean release agents and material buildup from molds

DUST COLLECTORS

ZERO RP dust collectors trap 99.7% of dust particles down to 0.5 micron.

CDC-1 dust collectors come in three sizes; 300 cfm, 600 cfm, and 900 cfm. The cartridges are pulse-cleaned by pressing the manual pulse-valve to clear the filter of dust. Dimensions are 34″ wide, 42″ deep (with motor housing) and 94″ high. MAH is 11 ft for the 300 cfm and 600 cfm units and 12-1/2 ft for the 900 cfm unit.

The RPC-2 has two cartridges which provide 470 sq ft of filter area. The cartridges are automatically pulse-cleaned for maximum filter efficiency. Dimensions are: 56″ wide (with motor housing) by 30″ deep by 67.5″ high. The MAH for the RPC-2 series is 8 ft 10 inches.

The RPH-2 has a filter area of 470 sq ft; the RPH-3 has a 705 sq ft filter area. Both have a built-in hopper to minimize dust-handling. At each pulse, dust falls first into the hopper and then into a disposal drum or bag beneath it. The operator never handles the dust—an important safety feature. RPH dust collector dimensions are: 56″ wide (with motor housing) by 36″ deep by 115″ high. The RPH is designed to allow outdoor installation. The MAH for the RPH collectors is 15 ft 2 inch.