BIG CLEMS—BULK ABRASIVE BLAST MACHINES LESS TIME REFILLING, MORE TIME BLASTING.

Clemco Bulk Blast Machines are supersized versions of our Classic Blast Machines. We call them Big Clems and manufacture them in 60-cuft, 120-cuft, and 160-cuft sizes. These machines handle large amounts of abrasive loaded at one time—and less time refilling means more time blasting. All Big Clems are equipped with two operator stations, and the 120-cuft and 160-cuft models can optionally be fitted with three or four stations. Each operator station has a pneumatic (optional electric) pressure hold remote control, which enables operators to independently start and stop. Big Clems blast with most media— expendable mineral, slag abrasives, steel grit, and more. In addition, they come in stationary, yard-towable, and highway towable designs, and all are equipped with 1.5” piping and 150-psi working pressure.

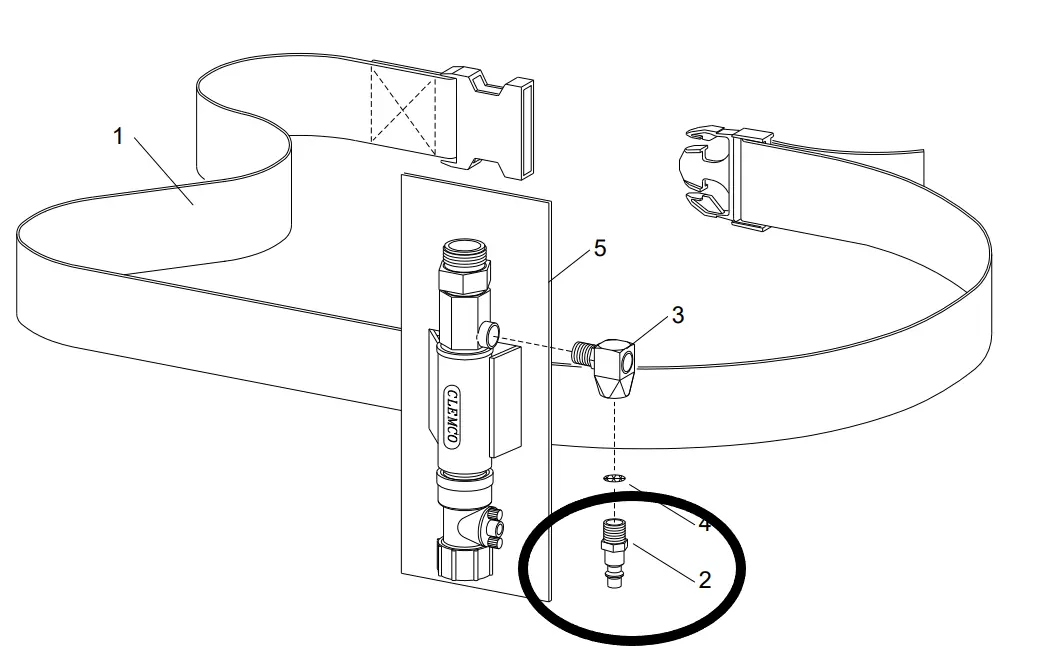

PRESSURE-HOLD REMOTE CONTROLS

• Enable operators to independently start and stop blasting.

• Pneumatic standard; optional electric.

• Abrasive cutoff system (ACS) allows work surface blow-off and clearing of blast hose.

• Fail-to-safe, normally closed design. Requires compressed air to open.

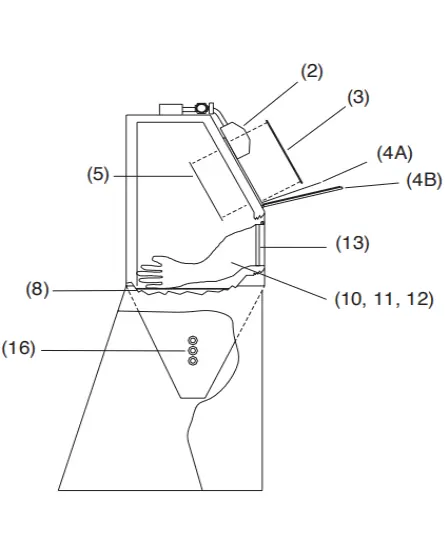

AUTOMATIC POP-UP FILLING VALVE

• Comes with a debris screen and a swing-open rain cap.

• Ladder allows easy access to pop-up valve for adding abrasive.

• Cannot be opened while machine is under pressure.

• Safest option on the market— eliminates the potential for injury on units with camlock closures.

INTEGRAL 1,600 CFM MOISTURE SEPARATOR AND AIR MANIFOLD

• Eliminates restrictions that cause airflow loss.

• Supports up to four No. 8 nozzles.

• Provides equal amounts of moisture free air to each operator. Moisture is a naturally occurring byproduct of compressed air.