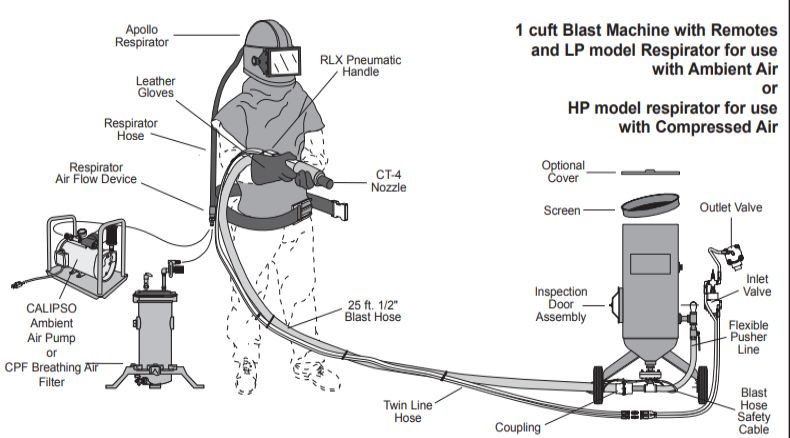

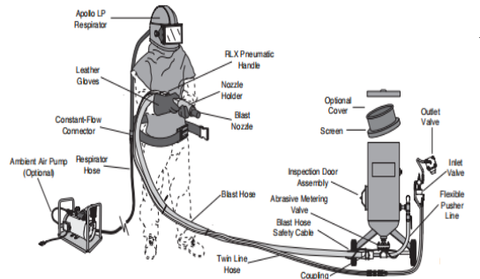

1 Cuft Classic Blast Machine System with 1/2″ piping

Field-portable, light-duty, industrial, single-chamber blast machine rated at 125 psi working pressure. Model 1042 holds 1 cubic foot of media (100 lbs expendable, mineral abrasive). This unit is equipped with MSV abrasive metering valve.

Purpose

High-performance, versatile blast cleaning system removes contamination, corrosion, mill scale, and coatings from most surfaces. Produces a uniform surface texture, and creates a surface profile to increase bonding for coatings. See related literature for additional applications Model 1042 holds 1 cubic foot of abrasive providing 15 minutes of blasting at 80 psi with a No. 4 (1/4-inch) nozzle. This unit can operate with as little as 12 cfm of air volume.

Requirements for Operation

These items are required but not included with this equipment:

• Clean, dry, compressed air of sufficient volume to maintain desired pressure at the nozzle. Refer to Air Consumption Chart in Blast Off 2 booklet (publication stock no. 09294).

• Minimum 12 cfm at 50 psi needed to close the pop-up valve and pressurize the blast machine.

• OSHA-required remote control system that interrupts blasting if operator should lose control of the nozzle when blast machine is pressurized.

• NIOSH-approved, type CE, supplied- air respirator.

• Grade D breathing-air supply as defined by Compressed Gas Association Commodity Specification: G-7.1 (Refer to www.cganet.com).

• Abrasive blast media specifically manufactured for abrasive blasting and appropriate for your application.

• Appropriate blast suit, work boots, hearing and eye protection

Description of Operation

The operator controls blasting from a remote control handle at the nozzle. Pressing the handle starts blasting; releasing it stops blasting. The blast machine contains abrasive and meters it into the compressed air stream.

Approvals and Certifications

Blast machine pressure vessel built to American Society of Mechanical Engineers (ASME) specifications for 125-psi working pressure. Vessel is hydrostatically tested and National Board-certified.

Remote control system complies with OSHA regulation 1910.244 (b).

Advantages

• One-man portable industrial-quality blast machines manufactured to ASME code.

• Industrial-quality valves, piping and fittings designed to maximize air flow and minimize energy required to operate the system.

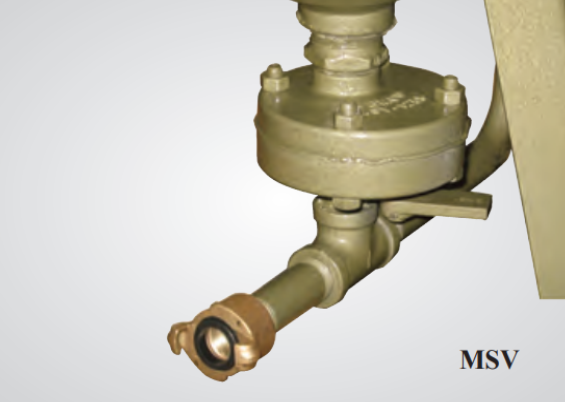

• MSV abrasive metering valve maintains smooth, consistent, adjustable media flow.

• State-of-the-art NIOSH-approved respirator with DLX comfort-fit suspension.

Includes

- TLR-50 remote controls (includes 10565 RLX handle) 02518

- MSV 1/2” abrasive metering valve 01247

- 25 ft. X 1/2” ID blast hose, coupled 01268

- CHE-1/2 aluminum nozzle holder (included in 01268) 00577

- CQA-1/2 aluminum quick coupling (included in 01268) 00599

- Blast hose safety cable 15012

- 1/2” Air filter with manual drain 01308

- CT-4 blast nozzle 01353

- Blast machine screen (optional steel cover) 03362 (03107)

- Nylon tie (eight included with system) 02195 (each)

- Apollo 20 LP DLX helmet with Constant Flow Connector 21299

- 50 ft respirator hose, coupled 22510

- One pair leather gloves 02243

- One 25-pack Apollo 20 outer lens 21411

- One 10-pack quick coupling gaskets 00850

- One 10-pack nozzle washers 21580

- Outlet valve diaphragms (three included with system) 02511 (each)

The MSV is a manual valve suited for expendable media; it is used on our 1/2-

and 1-cubic foot machines.

(-) MSV Metering Valve …. 01247

1. MSV top casting ………… 01258

2. Gasket, valve body…….. 01260

3. Metering plate & stem … 01261

4. O-ring……………………….. 00794

5. Pin, spring…………………. 01263

6. Washer, nylon……………. 01266

7. MSV bottom casting …… 01259

8. Spring, 17/32” OD X 1”.. 02178

9. MSV Handle………………. 01262

10. Cap screw, 5/16-NC x 1-3/4”…. purchase locally

11. Nut, 5/16-NC hex… purchase locally