Respected for their energy saving capabilities and proven reliability

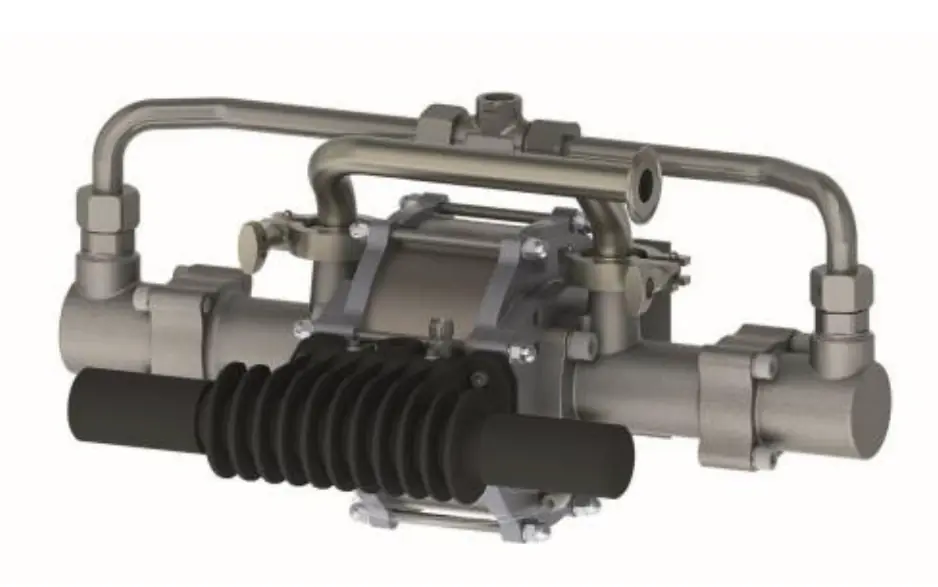

This is why they are found in the world’s largest Automotive OEM and Tier 1 paint shops. The Binks Smart Pumps use standard electric motors to drive the fluid section for pumping paints, solvents and other suitable materials. Smart pumps are available to suit a variety of flow requirements and the EV versions are retrofittable into the tightest paint kitchens

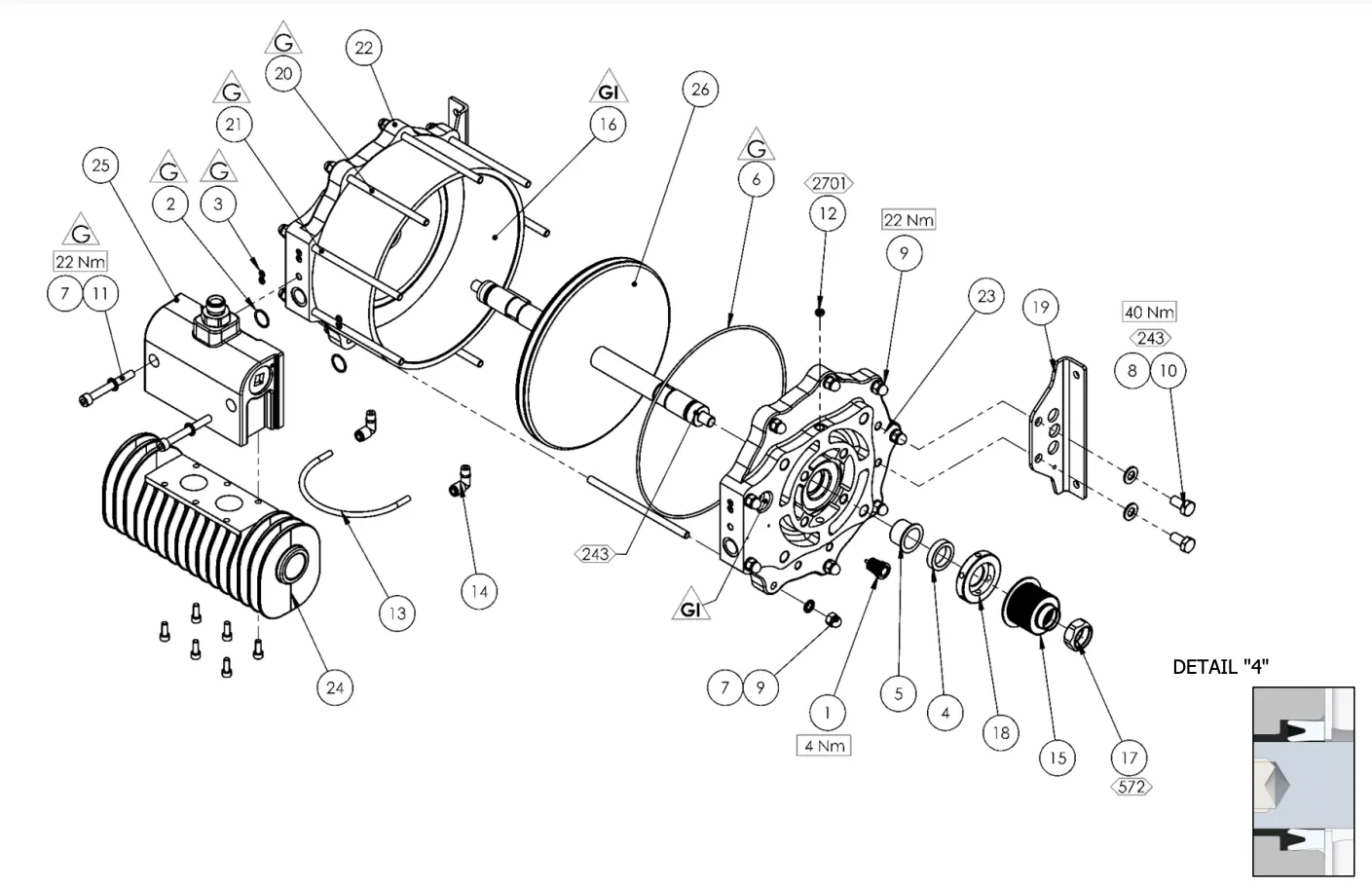

Smart pumps convert the rotary motion with a asymmetrical constant velocity cam. It ensures that there is always a piston generating pressure and eliminates pulsation and the need for a surge chamber. The fluid section design ensures the pump can run continuously and features a run to failure visual indication.

The Smart Pump system lowers operational cost compared to pneumatic pumps by monitoring and controlling pump speed and paint supply. During times of demand, pump speed and flow matches the demand at a constant pressure. At other times, pressure and flow are reduced, motor speed is lowered and energy is saved.

FEATURES

• Long life piston seals: Lubricated by paint on both sides to ensure no external leaks

• Ceramic coated pistons: Plus tungsten carbide seats for long working life

• Bellows shaft seal: Eliminate the need for shaft packing lubrication

• Auto lubrication system: Provides automatic carriage lubrication for up to a year

RECOMMENDED MATERIALS

• Solvent & Waterborne

• UV Cured

• Shear Sensitive Materials

• Moisture Sensitive Materials

TYPICAL APPLICATIONS

• Paint Circulation

| Min Flow 10 Cycles/Min | 0.44 gal. |

| Max Flow 40 Cycles/Min | 1.75 gal. |

| Cycle Displacement | 0.044 gal. |

| Max Pressure | 290 psi |

| Motor | 0.37 kW |

| Piggable Paint Circulation Compatibility | NO |

| Physical Dimensions (inches) | 36.1×12.8×39 |