The Maple Pump is our advanced, air operated, horizontal piston pump for automotive and general industrial applications. This range of precision engineered pumps is designed to handle modern shear sensitive solvent and waterborne paints as well as pure solvents and other paint shop materials. The Maple Pump design combines an energy efficient air motor with our low shear fluid section technology providing a smooth consistent flow of material for both automatic and manual spray gun systems.

- Advanced, air operated, horizontal piston pump

- Ideal for Automotive and General Industrial sectors

- Precision designed for multigun, paint transfer and circulating system applications

- Designed to handle modern shear sensitive solvent and waterborne paints as well as pure solvents and other paint shop materials.

- Horizontal fluid section handles shear sensitive materials with kid-gloves

- Reciprocating horizontal piston configuration provides smooth balanced fluid pressure on each stroke, reducing pressure fluctuations on changeover

- Low Ice, lubricant free air motor with patented quick exhaust technology significantly reduces the risk of valve icing

- Control valve metal spool and sleeve for long life, incorporating our patented magnetic detent to eliminate stall conditions

- Stainless steel fluid sections, ideal for waterborne, or solvent based paints.

- Tungsten Carbide ball seats and ceramic coated pistons ensure maximum, trouble free operating life

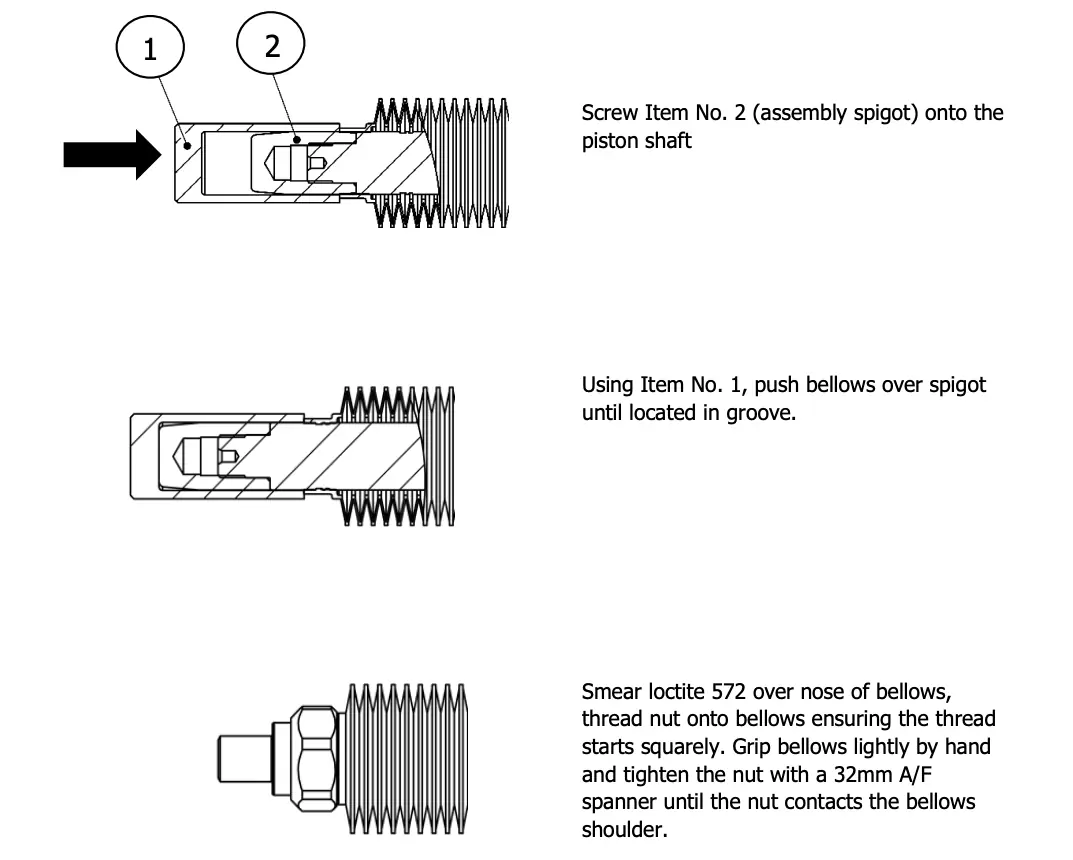

- Enclosed Bellows Seals – no exposed seals, eliminating shaft packing lubrication and significantly reducing pump maintenance

- Sanitary fluid connections guarantee a smooth internal flow and eliminate paint pockets to reduce the need for flushing and ensure a superior finish

- Binks 5 year warranty on materials and workmanship

Material

Ultra Violet (UV) Cure coatings

Moisture Sensitive Materials

Solvent and Waterborne Materials

Catalysed Spray Coatings

Stains, Varnish and Lacquers

Sealers and Undercoats

High Solid Coatings

Abrasive Coatings

Typical Applications Materials

Multi Gun Spray Booth

Auto Gun Spray Systems

Airless and Air Assisted Airless Applications

Wood & Component Finishing Flat Machines

Rotary Finishing Machines

Automatic Spray Reciprocators

Paint Circulating Systems

| Model Number | 30/3 |

| Ratio | 3:1 |

| Fluid output @60 cycles/min | 45 L/min |

| Max continuous cycle rate | 20 cycles/min |

| Max intermittent cycle | 40 cycles/min |

| Inlet fluid connection | 1.5″ Sanitary |

| Outlet fluid connection | 1.5″ Sanitary |

| Max air inlet pressure | 102psi |

| Compressed air Inlet | 3/8″ BSPP/NPSM |

| Air volume / cycle @ 45psi | 9.5 L/min |

| Air volume / cycle @ 90psi | 18.5 L/min |

| Weight | 77 lbs |

| Service Kits (Sold Seperately) | |

| Fluid Piston Seal Kit | 250608 |

| Fluid Section Overhaul Kit | 250619 |

| Air Motor Seal Kit | 250618 |

| Control Valve Kit | 250620 |