10 HP Air Compressor, 80 Gallon, 3 Phase,2 Stage Pressure Lubricated, Silent Air System, EMAX Industrial Plus

Silent Air Piston Air Compressor

Engineered and manufactured in the U.S.A. The whisper series compressors reduce stationary compressor DBA ratings by as much as 25%! A noise suppression device was first conceived by EMAX engineers after feedback from competitor compressor users revealed a large number of complaints regarding the extreme noise level of their compressors in a work environment. Stationary air compressor noise levels typically require owners to incur the added expense of a building or structure to house the compressor in an attempt to reduce noise in the work environment. The Whisper can be installed and operated in all Garage, Farm Shop, and Industrial applications which eliminate the need for traditionally expensive and often inadequate separate buildings or structures to house the air compressor. The Whisper silent air systems are already installed on the back of the tank with brackets that are fabricated for easy removal and low profile.

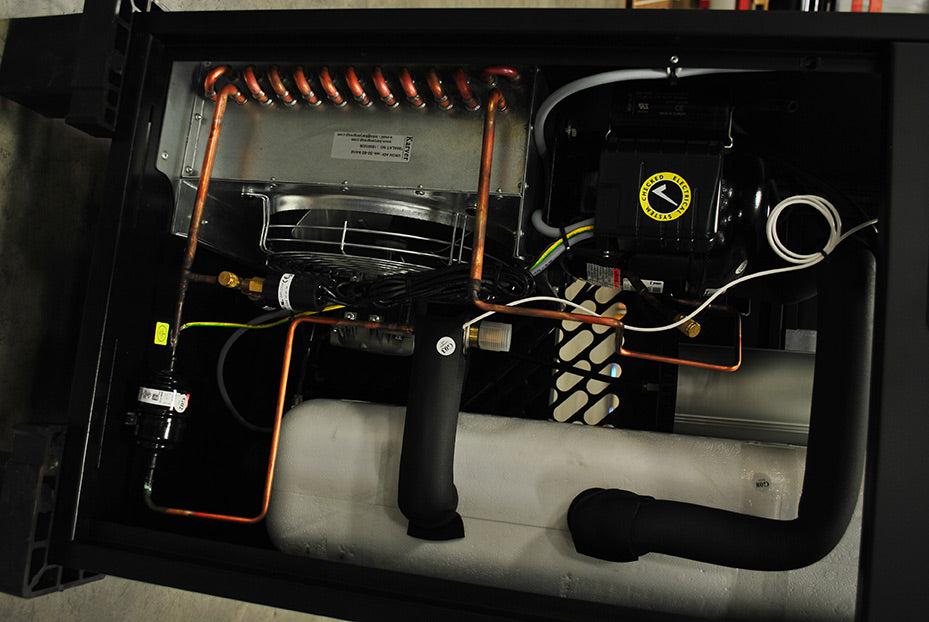

The Whisper dissipates compressor intake noise by channeling the intake air through a series of baffle plates and pre-filter media within the silencer cabinet. As a result, the piston intake noise is trapped and dissipated within the silencer structure. As a result, the piston intake noise is trapped and dissipated within the silencer structure. It also acts as a secondary filtration for cleaner air.

Patented Pressure Lubricated 2-stage cast iron pump with dual control design allows for automatic or continuous run rated at up to 70,000 hours based on B-10 bearing life rating

![]() At the core of our Emax compressors is our pump. These pumps are SUPER quiet in operation and built to last! We start with a solid cast iron crankcase. Unlike some competitor’s aluminum body crankcases – our solid cast iron crankcase will ensure stable crankshaft alignment and will handle more work load under heavy load conditions.

At the core of our Emax compressors is our pump. These pumps are SUPER quiet in operation and built to last! We start with a solid cast iron crankcase. Unlike some competitor’s aluminum body crankcases – our solid cast iron crankcase will ensure stable crankshaft alignment and will handle more work load under heavy load conditions.

Our pump also features a precision balanced solid cast iron crankshaft with Timken-Style stainless steel roller bearings on the front and rear of the crankshaft to ensure smooth & efficient operation with less drag and less energy use.

Our pumps also feature several other key components that ensure durability and performance!

- All steel connecting rods with replaceable rod bearing inserts. This allows our rods to be rebuilt! 99% of our competitors now use “throw-away” aluminum connecting rods in their pumps that have no re-build capability.

- Re-usable oil filter

- Oil Pressure Gauge

- Eligible for lifetime pump warranty

- Removable 100% cast iron cylinders. These solid cast iron cylinders are more stable under heavy workloads and do not warp from heat. Most of our competitors are using aluminum cylinders with a pressed-in sleeve that warp under extreme heat. This makes competitor pumps good for about a 40-50% duty cycle – while claiming a 100% duty cycle. Most of the pumps with aluminum cylinders have to be replaced in 1-2 years because they would not hold up under heavy use. Not our Air pumps! Our solid cast iron cylinders can “take the heat” and are designed to perform on heavy load demands.

- All cast iron cylinder heads. Cast iron heads are more durable and dependable for trouble free operation.

- “Disc valve design” intake and exhaust valves. Disc valves have been around for over 100 years and have been proven to perform. Most of our competitors are using “throw-away” reed valves which are not nearly as durable and can’t be re-built. Our disc valves come right out of the top of the cylinder head where they can be serviced in minutes instead of hours like reed valves.

- Top quality compression and oil rings. Our rings ensure performance with low oil carry over (1-5 PPM).

- Precision ground pistons machined to tight tolerances ensures low oil carry over.

- Premium “non-absorbent” gaskets prevent oil seepage from pump.

- All cast iron flywheel with built-in fan. The extra weight of our cast iron flywheel during run cycle gives the pump more “throw” on the compression stroke which will result in fewer loads on the electric motor. Some manufacturers use aluminum flywheels that do not have the proper weight ratio to give the proper throw on the compression stroke when the pump is running.

- Built-in head unloaders. These unloaders are built into the intake valve assembly on the compressor head and perform a valuable function. They unload or open the intake valves under constant run applications. This feature reduces internal pump heat from compression because the intake valve is held open throughout the unloading cycle. This allows fresh air to come into the cylinder chamber. Under the compression stroke, the unloader holds the intake valve open allowing the air to blow back out the intake filter. This fresh air absorbs the heat out of the pump under heavy workloads.

- Built-in inter-cooler and after-coolers. The inter-cooler allows air to be cooled between stages while the air cooled after-cooler provides a second cooling stage that cools the air before it goes into the tank. Our after-cooler also includes an all copper main feed line from the pump into the tank.

Bottom line …

Not only do we have one of the highest quality, most durable compressor pumps in the industry … but we have one of the lowest RPM compressor pumps on the market. That’s the Emax difference!

Pump RPM is a very critical factor in both performance and longevity. For that reason, on most of our compressors, we normally “GO BIG” over-sizing our pumps and running them at lower RPMs than most manufacturers. Our bigger, low RPM pump can still yield a high CFM output because both our bore and stroke are bigger. Not only do you get the big CFM output, but the lower RPM operation also reduces friction and heat buildup to extend pump life!

RAISED MOUNTING PLATFORM

Our raised pump platform design is a nice feature for keeping your oil cool within the pump. This platform raises the pump approximately 2” off the mounting base plate. This allows for 100% constant flow of cool air from the flywheel fan to circulate by not only the top & sides of the pump crankcase, but also opens the underside of the crankcase to cooling air flow. This ensures cooler oil temperatures within your pump. Cooler oil not only helps to lubricate the pump but also pulls the heat off the pistons and connecting rods – reducing wear and adding many years of life to the compressor pump.

NAME BRAND ELECTRIC MOTOR

A tough pump needs a tough motor that can drive it! Emax uses only high quality name brand premium efficiency motors that meet all UL and CSA requirements.

It is most important to note that all of our motors are low RPM motors (1750 rpm) … most manufacturers now use higher RPM motors (3450 rpm). 1750 RPM motors run much cooler than 3450 RPM motors because of the higher torque factor. They also yield low harmonic distortion, provide much higher torque in cold weather starting and require less electricity under start up.

The running and starting windings on these motors are all 100% copper wound for premium efficiency, reliable performance and durability. Buyer beware: some motor manufacturers actually use aluminum windings with a copper coating in their motors which will last a fraction of the time that copper wound motors will last.

Additional Motor Features:

- Large 1-3/8” output shaft

- High quality ball bearings on the front and rear of the motor shaft

- Large starting and running capacitors

- 15 Service Factor load. This means the motor can be pulled 15% over full load for more break horsepower

- Dynamically balanced armature for low vibration levels

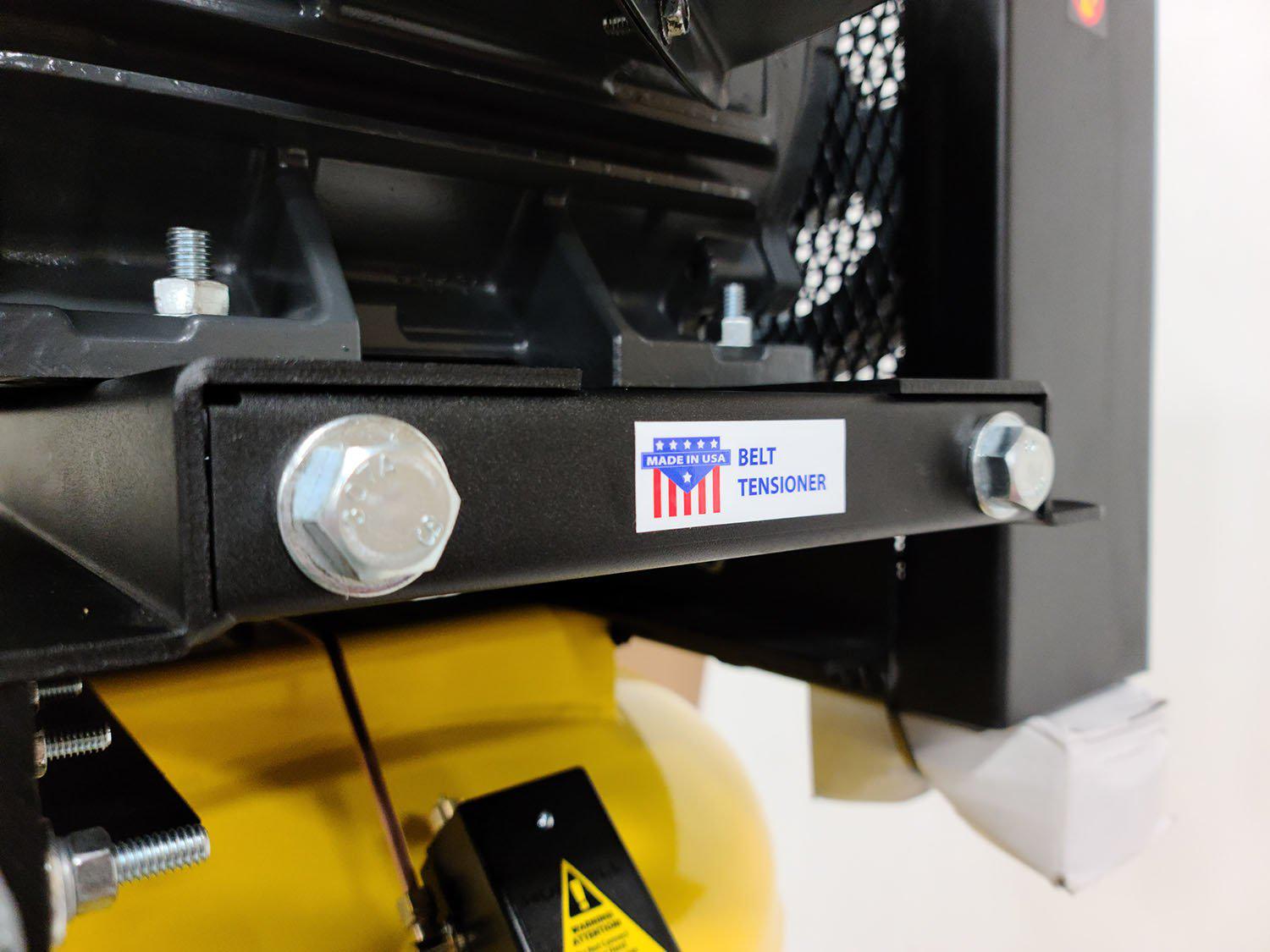

BELT TENSIONER

Your Emax compressor will come equipped with a proprietary design feature that will eliminate countless hours of maintenance and an equal amount of frustration. Our Automatic Belt Tensioner will allow you to adjust the tension and alignment of your belts with ease and in just minutes.

With Emax Compressors Automatic Belt Tensioner maintenance on your belt tension and alignment is not a problem anymore.

It’s easy, you’ll just loosen the 4 bolts under the motor about 2 threads – turn the adjustment bolt on the end of the belt tensioner assembly using a ¾” wrench until desired tension alignment is achieved – re-tighten the 4 motor mount bolts – and your done.

BELT GUARD

We at Emax Compressor are always concerned about durability and about your safety in everything we build. Our belt guards are no exception. Built right here in the USA with 13 G steel and premium grade expanded metal, we manufacture our belt guards to be tougher than any you will find in the industry today. For your safety, our belt guards are OSHA approved.

AIR TANK

We at Emax are always concerned about durability and about your safety in everything we build. Along with this philosophy, our air tanks are manufactured right here in the USA and are ASME code compliant in 50 states including California.

DUAL TIMER AUTOMATIC TANK DRAIN

Emax incorporates yet another standard value-added feature in it’s compressors that will eliminate maintenance and help to add years to the life of your air tank.

In hot, humid industrial environments, there is typically a lot of excess moisture in the air that is consumed into the compressor while under the intake & compression cycles. This moisture can then be transferred to the compressor into the air tank.

Additionally, if the compressor operates at a lower RPM and runs cooler (like our unit does) then water is condensed out of the air and collects in the air receiver. This water is harmful in many ways and must be drained out regularly.

First, it robs you of air capacity in your tank. Secondly, this moisture can be transferred through air lines into your equipment and/or tools.

Last, this water must be drained out regularly to avoid corrosion within your air tank which will shorten the overall life of your tank or worse yet result in tank failure.

Emax’s Automatic Tank Drain with Integrated Dual Timer will do this maintenance for you automatically on the time intervals you set to ensure that the condensation is removed regularly to avoid all of this.

CONTROLS & COMPONENTS

We at Emax Compressor use only top quality components on our compressors.

- Top quality pressure switches with an adjustable screw which allows you to adjust your pressure higher or lower.

- 100% brass check valves with Teflon Seating. All check valves on our compressors are all brass with a Teflon seating. This reduces tank noise when the compressor is running because the Teflon seating is much quieter than other materials and insulates noise when valves are opening and closing during the compression stage.

- 100% brass ASME safety valves. For your safety all safety valves are 100% brass and comply to ASME code. Valves are preset and sealed for correct settings. In the event that your compressor would not turn off, our safety valves open keeping compressor from building too high of a pressure level in the tank. This will help to avoid the potential of tank rupture.

- Top quality plumbing fittings are used to maintain proper sealing when connected to the tank.

- High quality 100% brass ball valves are used for turning air on and off from the air receiver.

- Extended tank water drain pipe plumbed out the front of the unit with a ¼” ball valve handle for easy tank draining. Eliminates the hassle of draining the tank with the typical petcock style drain under the tank.

- Load-less starting. Thanks to built-in head un-loaders built into the intake valve assembly on the compressor head, “load-less” staring is built into this unit. This unloads the pump so the pump will not start under direct head pressure. Without this feature, this will cause motor damage under starting cycle.

MAGNETIC STARTER

This unit has a prewired magnetic starter. A magnetic starter is necessary for any motor over 15 amps.

This greater amp load puts more load on the contacts. A typical pressure switch will not handle this greater load, so a prewired magnetic starter is required. The use of a magnetic starter gives you longer life on your controls because they are not overloaded and gives you trouble-free operation.

CONTINUOUS RUN & AUTOMATIC START/STOP

Emax Compressors come equipped with “continuous run” feature that maximizes performance and reduces wear on the internal components of your motor.

Under heavy workload applications such as sandblasting, your compressor can cycle on and off many times per hour. This constant cycling is causing more wear on the magnetic contacts in the motor because they are arching as the motor starts and stops.

If your workload is over 50% – 60% duty cycle we recommend engaging the continuous run feature to eliminate this “start & stop” arching and wear and tear on the magnetic contactors in your motor.

For normal workloads in your shop, you can turn off the continuous run and the unit will go back to automatic start/stop operation.

MOTOR PULLEY AND BELTS

We use taper lock style 2-groove pulleys (not single groove). We also use dual 2-groove, B-Style belts to drive our pumps. This combination is best for a couple of reasons.

First, dual belts ensure long belt life and yield low vibration which makes for smoother, more quiet operation because the dual belts do not have to be as tight as with a single belt setup. The tighter the belts (as with a single belt setup) the more load on the compressor pump and motor bearings which decreases the life of both.

Second, our taper lock pulleys are much better than a fixed bore pulley with a set screw. A taper lock design will lock the pulley in position to the motor shaft allowing it not to loosen or move on the motor shaft.

Our 5-year warranty should not only give you, our customer, complete confidence in our product – but also in our commitment to excellence in quality, support and service.