18 HP Gas Air Compressor, 2 Stage, V4, 30 Gallon, Truck Mount, EGES1830ST

18-HP Honda GX Engine w/ Electric Start

OHV design provides excellent torque and fuel efficiency

Provides long life and proven durability

Flow-Tek – Concentric Disc Valves

Delivers maximum air flow & reliability with low replacement cost

Cool-Tek – The Coolest Running Compressors In The Industry

35% lower operating temperature

Reduces moisture build up & extends pump life

Air-Stream Technology

Provides up to 50% longer pump life

Belt Tension Adjuster – Fast, Easy “One Turn” Design

Reduces vibration and extends belt life

Gate Valve Oil Drain

Provides quick, clean oil changes

The Difference

EMAX delivers overwhelming performance to ensure that they meet the needs of the most demanding environments. Our Pumps require less maintenance, service and downtime than any other compressors in the Air Industry’s. All our Products are designed with exacting tolerance and specifications to deliver all the power that is needed at the jobsite, garage or shop. EMAX Compressor industrial duty Gas Driven Air compressor series I number one in its class! These units are powered by one of the best name brand gasoline engines on the market, Honda GX series. Our full cast iron 2 stage compressor pumps are designed for longevity and power! This gas driven compressor comes with a 5 gallon mounted gas tank. All this is mounted on a 30 gallon power coated ASME certified air receiver.

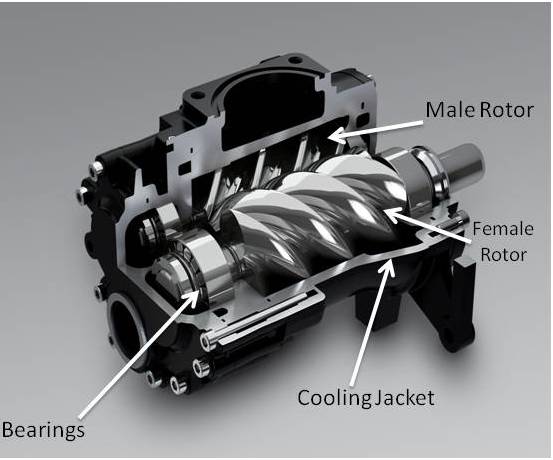

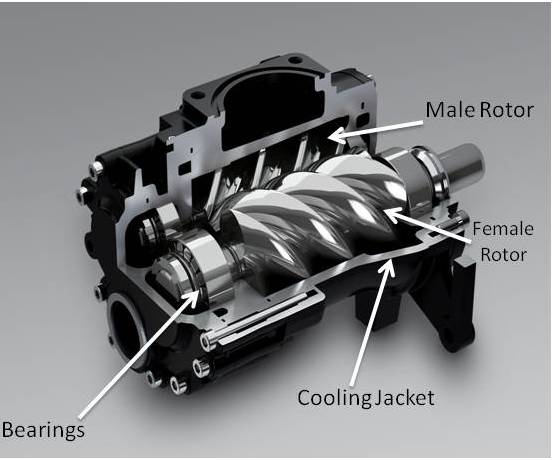

High Performance Pressure Lubricated Pump

We have designed our pumps to our last them all. We want to give you reliability no matter what job you are doing. We have designed our pumps with ALL cast iron! It has solid cast iron cylinder, cylinder heads, crankcase, flywheel, crank, and forged steel connecting rods – not aluminum! 99% of the pumps you see on the market today have aluminum rods. Heat can be your pumps worst enemy so we have designed our units with raised platforms to pull air under the pump to help cool the compressor. The V style shape of this pump also serves a purpose in that eliminates hotspots and gives consistent cooling. Remember a cooler a pump means a longer life.

This pump has large Timken-Style roller bearing on the crank ends on each end of the crankshaft. This ensures good crank stability and long compressor bearing life. Each cylinder is all cast iron with no sleeves or aluminum. All cast iron prevents cylinder distortion and egg-shaped cylinders when pump gets hot. This pump has 2 B-Section belt drive. Many of the pumps you see on the market have one belt…this is twin belt. Twin belt ensures better belt gripage and longer belt life. This pump has head unloaders. This is very nice for continuous run applications such as gasoline driven or electric driven high duty cycle applications. Head unloaders are an air cylinder in each head. When air is applied to them, they open or push the intake valves open allowing the pump to go into a free wheel mode. The cylinders are still moving in a free wheel mode, but it cannot compress the air because the intake valve is held open. This pulls cool air into the cylinder. The cool air absorbs the heat in the pump and blows it back out the intake valve. This is nice when you are sandblasting, etc., under heavy duty cycles. This pump has a site glass to view your oil level.

Some of the competition’s RPM are almost 1/2 or double the RPM of our pump because they are much smaller and have to run fast to produce the air. This pump has 1-piece connecting rod (all STEEL…not aluminum) with a re-buildable rod-to-crank bearing insert. This pump has valves intake and exhaust that are concentric ring valves or disk valves. These valves can be taken out of the head without touching a head gasket. They are sealed by an O-ring. It does not have reed valve system – disk valve are a much better valve design. Disk valves have been in quality compressors for over 100 years. This pump has intercooler and after cooler lines. The intercooler cools the air between stages and the after cooler cools the air after it comes out of the 2nd stage.

Power

EMAX only uses high quality, high performance components to build their compressors. So when it came to choosing who was going to power our gas driven compressors there was no other choice then Honda GX Series! The Honda GX V Twin engines have higher horsepower, quiet operation and greater fuel efficiency along with easy operation.

The V twin engine is designed to allow more air flow and better cooling. More cooling means better combustion as well and since Honda has put the two together you get greater durability, which means longer life! The 5 gallon gas tank that we have mounted to the tank lets you work longer between fill ups.

The Honda Engine is–SUPER smooth running! Electric start, slant cylinder design for smoother motor operation, muffler has spark arrester and ensures super quiet operation, overhead valve design, hydraulic valve lifters, low oil shutdown, automatic engine decompression release for easy starting, fuel tank reservoir, key switch, and battery charger. This motor also has an electronic ignition-no points to fool with. This engine also has an engine idle-down when unit is in free-wheel mode. This motor has very good cold weather starting ability. Motor carries a 3-year warranty from Honda and can be serviced at any of the Honda service centers in your area.

The set up

This unit has a 30-gallon ASME-approved air receiver and a custom-built engine stand under the engine. This braces the platform of the tank and is easy for belt tightening. By using this platform under the engine, this unit is super smooth without hardly any vibration whatsoever. This unit runs as smooth as one of our electric driven units except for a little engine noise. The air receiver has a drain 1/4″ ball valve coming out of the front of the tank so you have easy access for draining. We use a quality tank gauge and all safety valves and pop-offs are ASME approved. Unit has a 3/4″ ball valve as an air outlet. Our belt guard is custom built here at our factory. It is heavy duty-13 gauge expanded metal. This allows quiet operation and not a lot of vibration or noisy operation. This unit just needs a 12-volt battery and 2 battery cables, set it in your service truck, and it is ready to go. These units are pretested before they leave our factory.