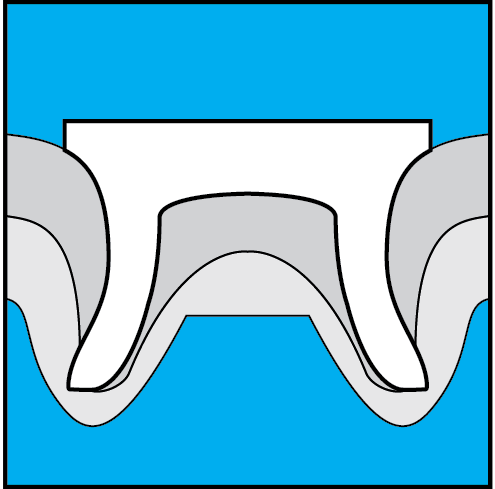

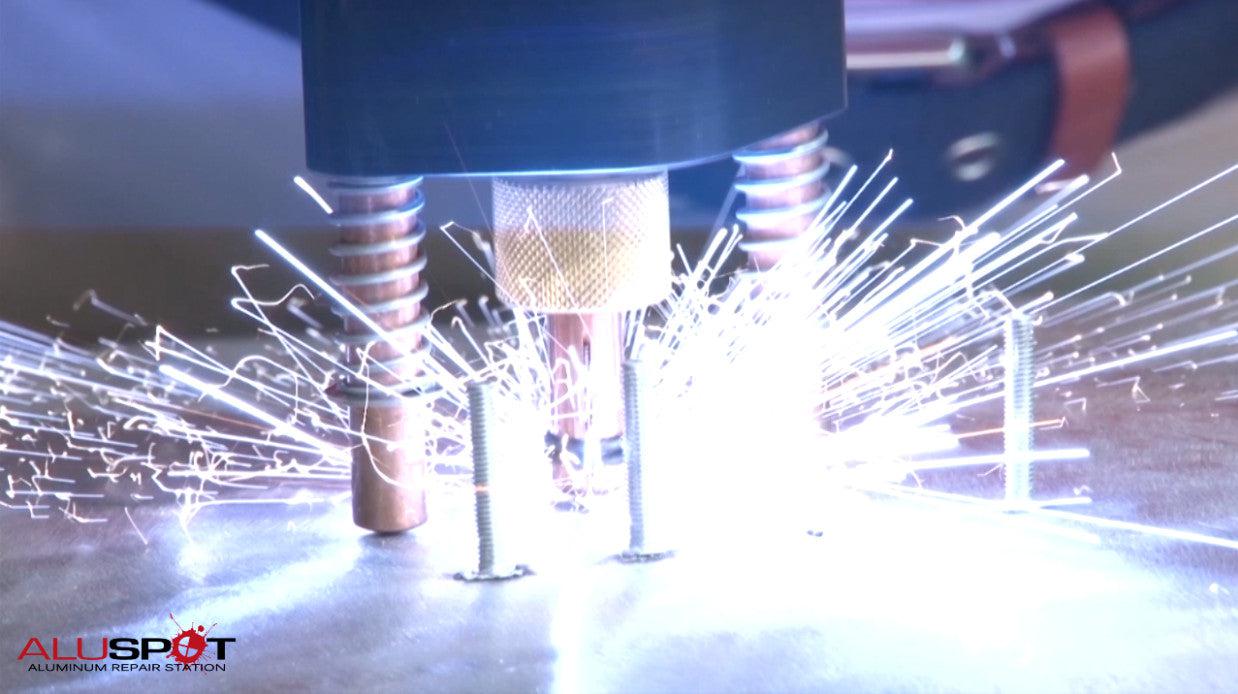

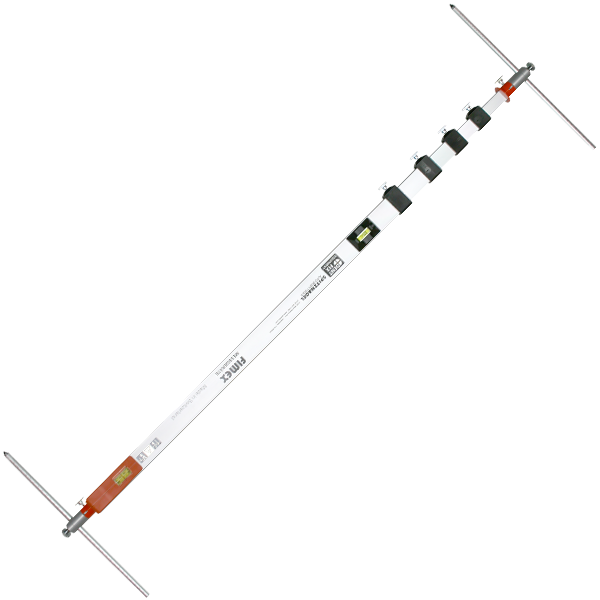

The Self-Piercing Riveter 10T DF-SPR70 is part of most OEM recommended methods for joining aluminum panels together. The cold forming technique requires no heat and no pre-drilled holes. The user can manually adjust the actuator speed as well as rivet pressure according to the metal used in order to avoid panel distortion. Dent Fix’s Self-Piercing Riveter is a reliable tool for riveting aluminum panels (up to 6.5mm with the rivets included in the kit but with optional longer 11mm rivets it can be used to assemble panel thickness of 8 to 9mm) together with high dynamic strength. The 10T pressure and included punching die allows for punching through boron steel in order to install flow-form rivets. The pressure and speed controls increases accuracy and enable the rivets to be inserted without panel distortion. A pressure gauge on the unit illustrates current pressure amount for controlled operation.

APPLICATION

Automatic air powered riveter designed to perform common riveting tasks in modern bodyshops including self-piercing rivets and standard flow form rivets.

FEATURE & BENEFITS

• 10 TONS – High pressure SPR capable of handling heavy duty installs.

• PRESSURE CONTROL – Adjustable dial with an easy to read gauge for ultimate control.

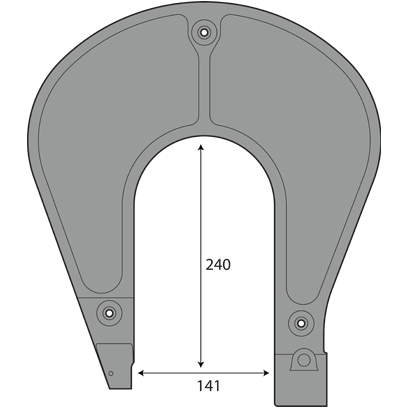

• ARM SWIVELS 360˚– C-Arm swings around into multiple positions for maximum access flexibility.

• ERGONOMIC HANDLE – Comfortable operation and stability.

• MAGNETIC DIE– Makes rivet positioning effortless and simple.

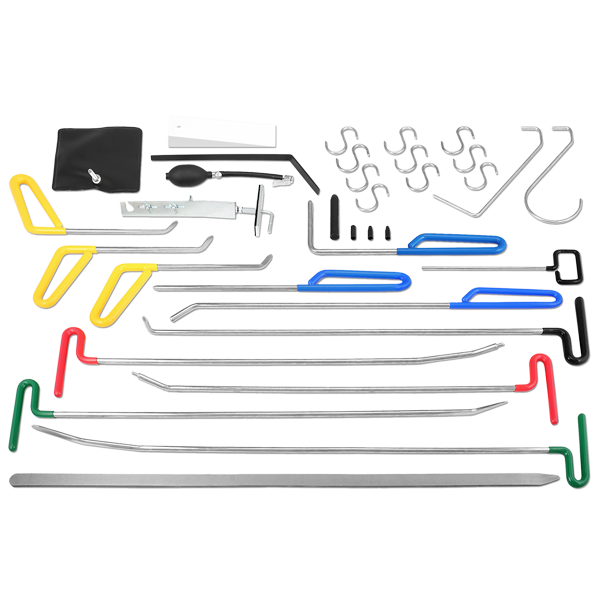

Kit includes matrices (3mm SPR, 5mm SPR, Extracting, Flow Form, 6.5mm Hole Punch), 2 matrix keys, center punch, strap, HR110 arm, a sample box of a variety of steel punch rivets, and a carrying case.1 Year Warranty.

SPECIFICATIONS

MAX PRESSURE: 10 Tons

BODY WEIGHT: 8.8 lbs

ARM WEIGHT: 6.6 lbs

CYCLE TIME: 4 Seconds

HYDRAULIC SYSTEM: Closed

SPR DIE SETS: 3.3mm & 5.3mm

EXTRACTION DIE SET: Yes

FLOW FORM DIE SET: 6mm

PUNCH DIE SET: Yes

FLATTENING DIE SET: Yes

CENTER PUNCH: One

STORAGE

Rugged plastic case with foam cut out inserts to secure the equipment in a safe place.