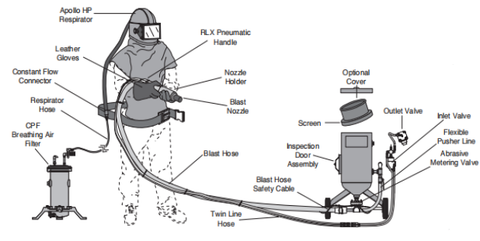

CLEMCO MODEL 1028 HP COMPLETE PACKAGE

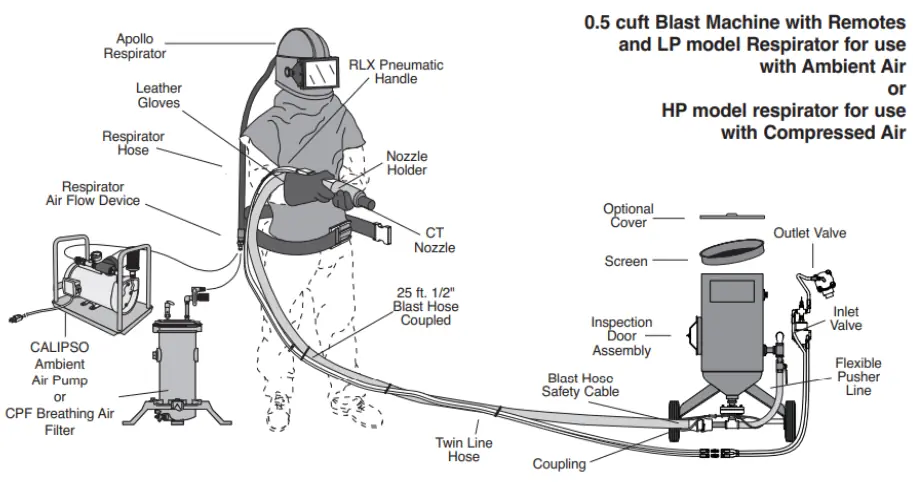

CLASSIC BLAST MACHINE PACKAGES WITH APOLLO LP

High-performance, versatile blast cleaning system removes contamination, corrosion, mill scale, and coatings from most surfaces. Produces a uniform surface texture, and creates a surface profile to increase bonding for coatings.

Requirements for Operation

These items are required but not included with this equipment:

- Clean, dry, compressed air of sufficient volume to maintain desired pressure at the nozzle. Refer to Air Consumption Chart in Blast Off 2 booklet (publication stock no. 09294).

- Minimum of 50 psi needed to close the pop-up valve and pressurize the blast machine.

- OSHA-required remote control system that interrupts blasting if operator should lose control of the nozzle when blast machine is pressurized.

- NIOSH-approved, type CE, supplied-air respirator.

- Grade D breathing-air supply as defined by Compressed Gas Association Commodity Specification: G-7.1 (Refer to www.cganet.com).

- Abrasive blast media specifically marketed for abrasive blasting and appropriate for your application.

- Appropriate blast suit, work boots, hearing and eye protection.

Description of Operation

The operator controls blasting from a remote control handle at the nozzle. Pressing the handle starts blasting; releasing it stops blasting. The blast machine contains abrasive and meters it into the compressed air stream.

Advantages

- Yard portable, industrial-quality blast machines manufactured to ASME code.

- 1-1/4-inch piping allows up to 50 percent more air flow when compared with 1-inch piping.

- Industrial-quality valves, piping and fittings designed to maximize air flow and minimize energy required to operate the system.

- FSV abrasive metering valve maintains smooth, consistent, adjustable media flow. Model 2443 Lo-Pot has a LPV abrasive metering valve.

Includes

- TLR-50 remote controls (includes 10565 RLX handle) 02518

- MSV 1/2” abrasive metering valve 01247

- 25 ft. X 1/2” ID blast hose, coupled 01268

- CHE-1/2 aluminum nozzle holder (included in 01268) 00577

- CQA-1/2 aluminum quick coupling (included in 01268) 00599

- Blast hose safety cable 15012

- 1/2” Air filter with manual drain 01308

- CT-4 blast nozzle 01353

- Blast machine screen (optional steel cover) 03362 (03107)

- Nylon tie (eight included with system) 02195 (each)

- Apollo 20 HP DLX helmet with Constant Flow Connector 20975

- 25 ft respirator hose 04397

- CPF-20 Breathing air filter 03578

- One pair leather gloves 02243

- One 25-pack Apollo 20 outer lens 21411

- One 10-pack quick coupling gaskets 00850

- One 10-pack nozzle washers 21580

- Outlet valve diaphragms (three included with system) 02511 (each)

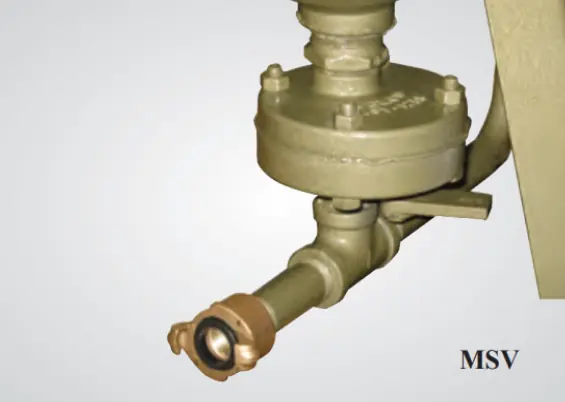

The MSV is a manual valve suited for expendable media; it is used on our 1/2-

and 1-cubic foot machines.

(-) MSV Metering Valve …. 01247

1. MSV top casting ………… 01258

2. Gasket, valve body…….. 01260

3. Metering plate & stem … 01261

4. O-ring……………………….. 00794

5. Pin, spring…………………. 01263

6. Washer, nylon……………. 01266

7. MSV bottom casting …… 01259

8. Spring, 17/32” OD X 1”.. 02178

9. MSV Handle………………. 01262

10. Cap screw, 5/16-NC x 1-3/4”…. purchase locally

11. Nut, 5/16-NC hex… purchase locally

Approvals and Certifications

Clemco’s quality management system is ISO 9001-2008 certified.

Blast machine pressure vessel built to American Society of Mechanical Engineers (ASME) specifications for 150-psi working pressure. Vessel is hydrostatically tested and National Board-certified.

Remote control system complies with OSHA regulation 1910.244 (b).