RANSBURG 19372-25N GUN ASSY,#2 (ELEC.)

This is a method of applying electrostatically at-omized coating material. The No. 2 Electric Pro-cess Handgun system applies a high voltage,DC negative charge to the applicator bell, creating an electrostatic field between the bell and the target object. The target is electrically grounded through its support (which may be stationary or moving) or through an electrical connection to a known earth ground.

A regulated pressure fluid system delivers coating material to the electric motor driven bell when the gun is triggered. There, the fluid travels across the face of the rotating bell andis charged. The fluid is atomized at the edge of the bell forming a fine mist, which under the influence of the electrostatic field is attracted to and deposited on the target object. The forces between the charged particles and the grounded target are sufficient to turn most normal over-spray around and deposit it on the rear surface of the target. Therefore, most of the spray is deposited and overspray is controlled. This process makes the No. 2 Electric Process Hand gunone of the most efficient electrostatic spray products on the market.

The No. 2 Electric Process Handgun applies a DC negative charge to the coating materials at the point of atomization. The electrostatic charge allows a more efficient, uniform application of coating material to the front, edges, sides,and back of products, making it highly suitable for applying coatings to a variety of surface configurations; large targets, tubular products, smallparts, fencing, etc. Because it is a grounded fluid system, it is highly suitable for applying aAH-13-01.3No. 2 Process Electric Motor Version – INTRODUCTION wide range of solvent reduced coatings such as enamels, epoxies, etc.

One of the many features of the No. 2 Electric Process Handgun is that the electrical discharge,which is available from the resistive charging brush, is limited to the optimum combination of safety and efficiency.

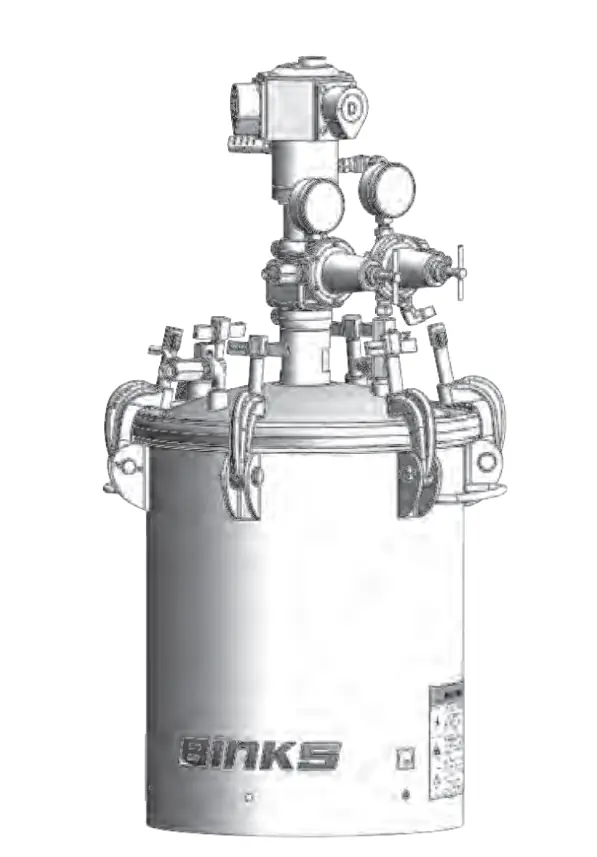

The No. 2 Electric Process Handgun system includes the Hand Gun, the High Voltage Power Supply, the High Voltage Cable, and Fluid Hose.This unit contains the 19372-XX No. 2 handgun electric motor version and the 80102-21X 9060 power supply along with several required accessories. Below illustrates the ordering matrix available.

- “Pure” electrostatic atomization – highest transfer efficiency

- Tried and tested technology

- Almost no overspray

- 90KV sprays most types of paints and fluids

- On-site Deuce units available

- 3 bell sizes for all industrial applications

- Air turbine bell rotation

Typical Applications

- Wrought Iron furniture and metal products

- Fences, Gates, Railings and many other Intricate metal parts

- On-site Office Furniture refurbishment

- Wire and screen products

- Chain-link fencing

- Security doors, fixtures and fittings

- Government maintenance departments

- Recreational park fences and playgrounds

| Fluid Input Pressure: | 50 PSI |

| Air Input Pressure: | 100 PSI |

| Fluid Delivery Rate: | |

| 2-3/4″ Bell: | 75 cc/minute(2.5 fl oz/minute) |

| 4″ Bell: | 120 cc/minute(4 fl oz/minute) |

| 6″ Bell: | 180 cc/minute(6 fl oz/minute) |

| Application Rate: | |

| 2-3/4″ Bell: | 5-7 ft/minute2(.46-.65 m/minute) |

| 4″ Bell: | 10-12 ft/minute2(.93-1.11 m/minute) |

| 6″ Bell: | 215-18 ft/minute2(.93-1.11 m/minute) |

| Input Voltage: | 110 or 220 VAC |

| Output Voltage: | 90 kV DC (negative) |

| Current: | 30-50 microamperes(operating) |

| SCI (From Brush): | 115 microamperes |